Product Description

Product Description

Free Forging and Open Die Forging factory for 30 years. ZPMC, NGC and ZheJiang Electric long term stable supplier.

Our Forged Steel Products

Tiangong Forging supplies a variety of semi-finished forged steel products, with the main materials being nickel-molybdenum steel, alloy steel, die steel, stainless steel and carbon steel. In addition to general steel grades such as 35#, 45#, 42CrMo, 42CrMo4, 18CrNiMo7-6, 20CrNi2Mo, 30CrNiMo8 and etc., we can also prepare the required steel according to other national specifications or specified alloy compositions requested by customers.

The maximum production shaft forging length/weight is 12m/15T; the maximum gear and wheel forging diameter/weight is 1.9m/9T.

We are particularly specialized in the forging of special-shaped forging parts.

Our main products:

A.Forged Gear Blank

B.Wheel and Pulley

C.Forged Shaft

D.Hollow Shaft

E.Crankshaft

F.Multi-stepped Shaft

G.Various forged blank and block

I. Special-shaped Forging Parts

Product Parameters

Our open die forging process capabilities include:

|

ITEM |

MAX OD |

MAX HEIGHT |

|

Gear |

120″ |

20″ |

|

ITEM |

MAX OD |

MAX THICKNESS |

|

RECTANGLE / BLOCKS |

20″ |

8,000 |

|

ITEM |

MAX DIAMETER |

MAX LENGTH |

|

SHAFTS |

36″ |

78″ |

|

ITEM |

MAX OD |

MAX LENGTH |

|

CYLINDERS |

50″ |

40″ |

More Products

Production Flow Chart

Certifications

Factory Show

Our company located in HangZhou city, ZheJiang province. Neaby ZheJiang . With over 30 years of forging experience. Our focus is on using high-efficiency electro-hydraulic hammer facilities to produce free forged and open-die forged products.

We are proud of our independent quality assurance laboratory, which ensures that all of our products meet our customers’ requirements.

A. More than 25 years of professional free forging and open-die forging manufacturing experience

B. The company covers an area of 71,000 square meters

C. The construction area of the production workshop is 12,000 square meters

D. Total number of employees: 158

E. 28 engineering and technical personnel

F. 59 skilled workers

G. Annual production capacity is 38,000 tons

H. Annual raw material steel throughput turnover reaches 56,000 tons

Reliable production

At Tiangong Forging, we invest in production equipment every year to maintain and further improve the quality of our products.

The only way to achieve the required quality is to start with a correctly specified material and process it on an efficient forging machine. To ensure the final standards required by our customers, a correct and precisely controlled heat treatment process is a key factor.

Various types of high-precision machining equipment are also an important part of providing products with high customer satisfaction.

- 12 tons Electro-hydraulic Hammer with Operating Machine

- 8 tons Electro-hydraulic Hammer with Operating Machine

- 5 tons Electro-hydraulic Hammer with Operating Machine

- 20 tons Loader

- 5 tons Loader

- Natural Gas Pre-forging Heating Furnace

- Heat Treatment Electric Furnace

- There are 5 heat treatment electric furnaces with loading capacities of 5 tons, 15 tons, 50 tons, 60 tons and 60 tons respectively.

- Various Machining Equipment

- The machining center has multiple high-precision machining equipment such as CNC vertical lathes, CNC horizontal lathes, horizontal milling machines, radial drilling machines, ordinary horizontal lathes, sawing machines, etc

Main Mateirals: Carbon Steel, Stainless Steel and Alloy steels;

International Standards: ASME, JIS, DIN, GB, BS, EN, AS, SABS, etc.

Standardization and Customization are both our advantages.

Application:

Our parts are widely used in Chemical Industry, Wind power generator, Large machinery parts Chemical industry,Agricultural machinery parts ship shaft fittings. Wind Power gearbox Transmission system.

HangZhou Port, HangZhou automatic Port, ZheJiang Yang shan Port, Italy Vado port. ZheJiang Tailway crane, Egypt hanging bridge, Sri Lanka railway crane, Thailand port bridge. South Korea railway crane, Hongkong island bridge, Singapore railway crane, Russia oil & mining machines and some miltary project. etc.

Customized solutions

Our modular process allows us to design solutions various industrial application requiring free-forged and open-die-forged parts. Our modularity means flexibility, wide choice, faster delivery and, above all, competitiveness.

All Tiangong Forging, products and production processes are designed to ensure exceptional, reliable and long-lasting unique mechanical properties, thereby reducing operating costs and extending service life.

With an extensive product range and extensive experience gained in most industrial applications, we can also provide engineering advice to our customers.

Welcome to visit our factory! Welcome to send inquiry to us.

Welcom Trading compamy to co-operate.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Free Forging |

| Samples: |

US$ 1000/Ton

1 Ton(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

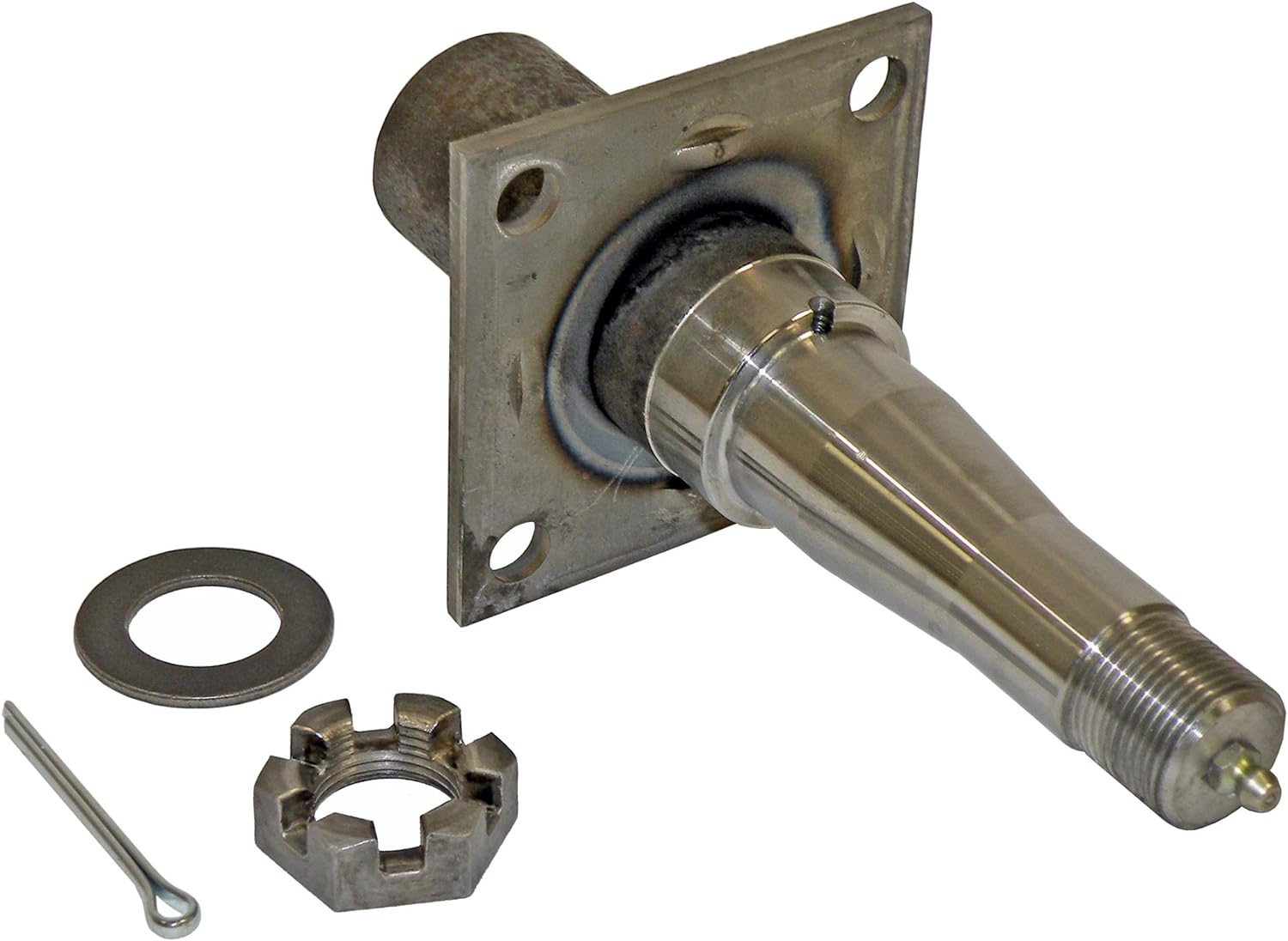

Are there specific tools required for removing and installing an axle spindle assembly?

Yes, removing and installing an axle spindle assembly typically requires specific tools to ensure the task is performed correctly and efficiently. Here’s a detailed explanation of some of the tools commonly used for this job:

- Hydraulic Jack and Jack Stands: These tools are used to safely lift and support the vehicle off the ground, providing access to the axle spindle assembly. A hydraulic jack is used to raise the vehicle, while jack stands are placed under the chassis to secure it at the desired height.

- Socket Set and Wrenches: A socket set with various socket sizes and wrenches is essential for loosening and tightening the fasteners that secure the axle spindle assembly and its associated components. These tools enable you to remove nuts, bolts, and other fasteners during disassembly and reinstall them during assembly.

- Pry Bar or Ball Joint Separator: A pry bar or a ball joint separator may be needed to separate ball joints, tie rod ends, or other connections that are attached to the axle spindle. These tools help to release the components without damaging them or the spindle assembly.

- Torque Wrench: To ensure proper torque specifications are met during assembly, a torque wrench is essential. It allows you to apply the correct amount of torque to the fasteners, ensuring they are neither too loose nor too tight. Over- or under-tightening can lead to component failure or damage.

- Axle Nut Socket: In some cases, a specialized socket known as an axle nut socket is required to remove and install the axle nut that secures the axle shaft to the wheel hub. This socket is designed to fit the specific size and shape of the axle nut, allowing for proper engagement and torque application.

- Bearing Puller or Press: Depending on the design of the wheel bearing assembly, a bearing puller or press may be necessary to remove the old bearing from the axle spindle or to install a new bearing. These tools ensure controlled and precise removal or installation of the bearing, minimizing the risk of damage to the spindle or the new bearing.

- Brake Tools: If the axle spindle is associated with the brake system, you may need specific brake tools such as a caliper piston tool, brake pad spreader, or brake bleeder kit to properly disassemble and reassemble the brake components during the axle spindle replacement.

- Shop Manual or Repair Guide: While not a physical tool, having access to the vehicle’s shop manual or a reliable repair guide is crucial. These resources provide step-by-step instructions, torque specifications, and other essential information specific to your vehicle make, model, and year.

It’s important to note that the specific tools required for removing and installing an axle spindle assembly can vary depending on the vehicle’s make, model, and design. Additionally, certain specialized tools may be needed for specific axle spindle configurations or unique components associated with the assembly.

Before attempting to replace an axle spindle assembly, it’s strongly recommended to consult the vehicle’s shop manual or a trusted repair guide to identify the specific tools required and to understand the proper procedures for your particular vehicle. If you lack the necessary tools or experience, it is advisable to seek assistance from a professional mechanic or technician who has the expertise and appropriate tools for the job.

In summary, specific tools are typically required for removing and installing an axle spindle assembly. These tools include a hydraulic jack, jack stands, socket set, wrenches, pry bar, torque wrench, axle nut socket, bearing puller or press, brake tools (if applicable), and access to a shop manual or repair guide. Utilizing the correct tools ensures that the job is performed safely and accurately.

Can axle spindles be upgraded for improved performance, and if so, what are the options?

Axle spindles can be upgraded to improve the performance of a vehicle, particularly in applications where higher strength, durability, or enhanced capabilities are desired. Upgrading axle spindles can provide benefits such as increased load capacity, improved off-road capability, or enhanced towing capabilities. Here are some options for upgrading axle spindles:

- High-Strength Axle Spindles: One option is to replace the stock axle spindles with high-strength counterparts. High-strength axle spindles are typically made from stronger materials or feature reinforced designs to handle heavier loads or harsher conditions. These upgraded spindles can enhance the overall strength and durability of the axle assembly.

- Performance Axle Spindles: Performance-oriented axle spindles are designed to improve the handling and responsiveness of the vehicle. These spindles may feature optimized geometry, reduced weight, or enhanced stiffness to provide better cornering abilities, reduced body roll, or improved steering precision. Performance axle spindles are commonly used in applications such as racing or high-performance vehicles.

- Off-Road Axle Spindles: Off-road enthusiasts may opt for axle spindles specifically designed for rugged terrains. These spindles often have increased ground clearance, improved articulation, or additional reinforcement to withstand the demands of off-road driving. They can enhance the vehicle’s off-road capability, allowing for traversing challenging obstacles and rough terrain more effectively.

- Towing and Hauling Axle Spindles: Upgraded axle spindles for towing or hauling purposes are engineered to handle heavier loads and provide increased stability. These spindles may have reinforced construction, larger bearings, or specialized features such as integrated trailer brake connections. Upgrading to towing or hauling axle spindles can enhance the vehicle’s towing capacity and improve overall towing performance.

- Custom Axle Spindles: In some cases, custom axle spindles can be fabricated or modified to meet specific performance requirements. This option is typically utilized in specialized vehicle applications or when specific performance goals cannot be achieved with off-the-shelf upgrades. Custom axle spindles allow for tailored solutions that can address unique needs and performance objectives.

When considering axle spindle upgrades, it is essential to ensure compatibility with other components of the axle assembly, such as bearings, hubs, and brakes. Upgrades may also require modifications to other parts of the vehicle, such as suspension systems or steering components, to optimize performance and maintain overall safety and reliability.

It is recommended to consult with knowledgeable professionals, such as experienced mechanics, axle specialists, or vehicle customization experts, to determine the most suitable upgrade options for your specific vehicle and performance goals. They can provide guidance on selecting the appropriate axle spindle upgrades and ensure proper installation and integration into the vehicle’s overall system.

What are the common signs of a worn or faulty axle spindle, and how can they be identified?

A worn or faulty axle spindle can exhibit several common signs that indicate potential issues. Here’s a detailed explanation:

Identifying a worn or faulty axle spindle requires careful observation of the vehicle’s behavior and performance. Here are some common signs that may indicate problems with the axle spindle:

- Uneven Tire Wear: Excessive or uneven tire wear is often a sign of a worn or faulty axle spindle. Inspect the tires regularly and look for patterns of wear, such as excessive wear on the edges, scalloping, cupping, or feathering. Uneven tire wear suggests that the spindle is not properly supporting the wheel assembly or that the alignment is compromised.

- Steering Instability: A worn or faulty axle spindle can cause steering instability. If you notice that the steering feels loose, imprecise, or requires constant correction while driving, it could be a sign of a problem with the spindle. Pay attention to any vibrations or shimmying sensations felt through the steering wheel, as these can also indicate issues with the axle spindle.

- Pulling or Drifting: If the vehicle consistently pulls to one side or drifts off-center, it may be due to a worn or faulty axle spindle. This misalignment can cause uneven tire wear and affect the vehicle’s stability and handling. Keep an eye on the vehicle’s tendency to deviate from a straight path while driving on a level road.

- Noise or Grinding: A worn or faulty axle spindle can produce unusual noises. Listen for any grinding, clicking, or humming sounds coming from the wheel area while driving, especially during turns. These noises may indicate worn or damaged bearings within the spindle assembly, which require immediate attention.

- Excessive Play or Movement: Check for excessive play or movement in the wheel assembly by firmly gripping the tire at the 12 o’clock and 6 o’clock positions and attempting to rock it back and forth. Excessive play or movement can suggest a worn or loose axle spindle, which can compromise the vehicle’s stability and handling.

If you observe any of these signs, it is recommended to have the axle spindle inspected by a qualified mechanic or technician who can assess the condition of the spindle and perform the necessary repairs or replacement.

In addition to visual inspection and observation of the mentioned signs, specialized diagnostic tools may be used to further evaluate the condition of the axle spindle. These tools can measure wheel alignment, detect excessive play or movement, and identify any abnormalities in the spindle assembly.

Regular maintenance and periodic inspections of the suspension system can help in identifying early signs of axle spindle wear or faults. It’s important to address any issues promptly to prevent further damage and ensure the optimal performance and safety of the vehicle.

In summary, common signs of a worn or faulty axle spindle include uneven tire wear, steering instability, pulling or drifting, unusual noises, and excessive play or movement in the wheel assembly. Careful observation, visual inspection, and professional evaluation can help identify these signs and determine the condition of the axle spindle.

editor by CX 2024-04-19

China high quality Hot Forged Alloy and Carbon Steel Shaft Forging Powder Exhaust Fan Spindle Trt Spindle with Best Sales

Product Description

Product Description

Hot Forged Alloy and Carbon Steel Shaft Forging Powder Exhaust Fan Spindle Trt Spindle

ZheJiang Qilu Industrial Co., Ltd has the capacity to guarantee the quality for every step, from raw material (forging), then heating treatment, finally machining. We have our own forging mill, heating teatment shop and machining shop. At present we could supply various of lage main shaft, turbin shaft, cylinder shaft, windy generator shaft, roller shaft, wheel forging, drill bit forging and kinds of irregular parts based on the drawing provided by customers.

Steel material for shaft and forging parts:

| Engineering Steel | |||||

| GB GB/T 700 |

JIS JIS G3101 |

DIN (W-Nr.) EN10571-2 / DIN17100 |

AISI/ASTM ASTM A36 |

BS | OTHERS |

| Q235B | SS400 | S235JR / RST37-2 | A36 | ||

| Q235C | S235J0 / ST37-3 U | ||||

| Q235D | S235J2 | ||||

| GB GB/T1591 |

JIS | DIN (W-Nr.) EN10571-2 / DIN17100 |

AISI/ASTM | BS | OTHERS |

| Q355B | S355JR | ||||

| Q355C | S355J0 / ST52-3U | ||||

| Q355D | S355J2 / ST52-3 N | ||||

| Q355E | S355K2 | ||||

| GB GB/T 699 |

JIS JIS G4051 |

DIN (W-Nr.) EN 10083-2 |

AISI/ASTM ASTM A20 |

BS | OTHERS |

| 1018 | EN2C | ||||

| 20 | S20C | C20 | 1571 | EN3B/070M20 | ASTM A105 |

| 35 | S35C | C30 | 1035 | ||

| 45 | S45C | C45E/1.1191 | 1045 | EN8D/080M40 | |

| 50 | S50C | C50/1.1206 | 1050 | 080M50 | |

| 55 | S55C | C55 | 1055 | EN9/070M55 | |

| GB GB/T 3077 |

JIS JIS G4105/JIS G4103 |

DIN (W-Nr.) EN 15710 |

AISI/ASTM ASTM A29 |

BS BS 970 |

OTHERS |

| 40Cr | SCr440 | 41Cr4(1.7035) | 5140 | ||

| 15CrMo | SCM415 | 16CrMo44/1.7337 | |||

| 20CrMo | SCM420 | 18CrMo4/1.7243 | 4118 | ||

| 30CrMo | SCM430 | 25CrMo4/1.7218 | 4130 | 708A25/708M25 | |

| 42CrMo | SCM440 | 42crmo4/1.7225 | 4140 | EN19/709M40 | |

| SCM445 | 4145 | ||||

| 40CrNiMoA | SNCM 439/SNCM8 | 36CrNiMo4/1.6511 | 4340 | EN24/817M40 | |

| 40NiMoCr10-5/1.6745 | EN26/826M40 | ||||

| 34CrNiMo6 / 1.6582 | 4337 | ||||

| 30CrNiMo16-6/1.6747 | 4330V | EN30B/835M30 | |||

| 32CrMo12/1.7361 | EN40B/722M24 | ||||

| 16CrMnH / 20CrMnTi | 16MnCr5 / 1.7131 | 5115 | |||

| 20CrMn | 20MnCr5 / 1.7147 | ||||

| 15CrNi6/1.5919 | 3115 | ||||

| 16NiCr4/1.5714 | EN351/637M17 | ||||

| 4615/4617 | EN34/665M17 | ||||

| 14NiCr14/1.5752 | 3310/3415 | EN36/655M13 | |||

| 15NiCrMo16-5/1.6723 | EN39/835M15 | ||||

| 17CrNiMo6 | 18CrNiMo7-6 (1.6587) | 4815 | |||

| 20CrNiMo | SNCM220 | 1.6523/21NiCrMo2 | 8620 | 805M20 | |

| 20CrNiMo5 | EN353 | ||||

| GCr15 | SUJ2 | 52100/1.3505 | EN31/535A99 | ||

| 38CrMoAl | SACM645 | 41CrAlMo7/34CrAlMo5 | 905M39/905M31 | 41CrAlMo74(ISO) | |

ZheJiang Qilu Industrial Co., Ltd were already engaged in exporting steel for 11 years, could supply a great variety of hot forged, hot rolled and cold drawn Steels, including engineering steel, cold work tool steel, hot work tool steel, plastic mold steel, spring steel, high speed steel, stainless steel etc., besides Qilu Industrial also has their own heating treatment shop and machining shop to provide heating treatment, cutting and further machining service.

Since 2008 year, ZheJiang Qilu Industrial has the right to export all FORGED STEEL behalf of Qilu Speical Steel Co.,ltd which is specialized in smelting and forging of special steel since 1965 year, now Qilu special steel is 1 of the biggest manufacturer of forged product in China.The forged products are used in Automotive, Aerospace, Power Generation, Oil & Gas, Transportation and Industrial.

Till 2013 year, many customers need HOT ROLLED and COLD DRAWN steel from Qilu Industrial, in order to provide one-stop solution to our customers, Qilu Industrial began to cooperate with Xihu (West Lake) Dis.bei Special Steel (HangZhou and HangZhou mill), Baosteel, Tiangong International, Changcheng Special Steel for hot rolled tool steel, cooperate with HangZhou Speical Steel, HangZhou HangZhou Speical Steel, Shagang Group, CZPT Group for hot rolled engineering steel. Now we already set up the warehouse in HangZhou and HangZhou City, more than 20000 tons ex-stock could be supplied with kinds of sizes.

Then from 2018 year, Qilu Industrial decide to provide further manufacturer processing service, at present we could supply various of lage main shaft, turbin shaft, cylinder shaft, windy generator shaft, roller shaft, wheel forging, drill bit forging and kinds of irregular parts based on the drawing provided by customers.

Qilu Industrial is the professional one-stop steel manufacturer, stockist and exporter in China, our customers spread all over the world, include West Europe, North America, South America, Asia, Middle Asia, Africa, Australia, etc.

The company owns advanced special steel smelting facilities and forging processing equipments, the main steel-making equipment include 2 sets of 50t ultra-high power electric arc furnaces,2 sets of 60t LF refining furnaces,1 set of 60t vacuum degassing refining CZPT and 4 sets of 1-20t electroslag re-melting furnaces.

The main forging equipments mainly include:3 sets of 5t electro-hydraulic hammers, 1 set of high-speed forging units of 800t,1600t,2000t and 4500t respectively.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Central Spindle |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Stepped Shaft |

| Customization: |

Available

| Customized Request |

|---|

Are there aftermarket axle spindle options available with enhanced durability or features?

Yes, there are aftermarket axle spindle options available that offer enhanced durability or additional features compared to the original equipment manufacturer (OEM) spindles. Here is a detailed explanation:

Aftermarket parts are manufactured by companies other than the vehicle’s original manufacturer. These companies often specialize in producing high-quality replacement parts that may offer improvements over the OEM components. When it comes to axle spindles, some aftermarket options are designed to provide enhanced durability or incorporate features that can benefit specific applications or driving conditions.

Here are a few examples of aftermarket axle spindle options with enhanced durability or features:

- Performance Spindles: Some aftermarket manufacturers offer performance-oriented axle spindles that are designed to handle higher loads and stress levels. These spindles are commonly used in applications where increased durability and strength are required, such as heavy-duty trucks, off-road vehicles, or vehicles used for towing. Performance spindles may be made of stronger materials or feature reinforced designs to withstand more demanding conditions.

- Upgraded Materials: Aftermarket axle spindles may be manufactured using advanced materials that offer improved strength and corrosion resistance compared to the original spindles. For example, spindles made from alloy steel or heat-treated steel alloys can provide enhanced durability and longevity, especially in harsh environments or applications subject to heavy loads.

- Improved Design and Engineering: Aftermarket manufacturers often analyze the weaknesses or limitations of OEM spindles and develop improved designs to address those issues. This may involve optimizing the geometry, reinforcing critical areas, or incorporating additional features for better performance. These enhanced designs can result in spindles that are more resistant to bending, warping, or premature wear, thereby increasing their durability.

- Specialized Spindles: In some cases, aftermarket axle spindles are designed for specific applications or driving conditions. For example, there may be spindles available that are specifically engineered for off-road use, providing improved ground clearance or compatibility with certain suspension systems. Likewise, there may be spindles designed for racing applications, where lightweight construction and enhanced performance characteristics are prioritized.

- Customization Options: Certain aftermarket manufacturers offer customized axle spindles that allow customers to tailor the spindles to their specific needs. This can include options for different bearing sizes, wheel bolt patterns, or spindle lengths to accommodate unique vehicle setups or modifications.

When considering aftermarket axle spindle options, it’s important to choose reputable manufacturers known for their quality and reliability. Look for spindles that meet industry standards and certifications, and consider factors such as the specific application, vehicle requirements, and intended use to ensure compatibility and optimal performance.

It’s also worth noting that while aftermarket axle spindles can offer enhanced durability or additional features, they may come at a higher cost compared to OEM replacements. However, the potential benefits in terms of improved performance, longevity, or customization options can make them a worthwhile investment, particularly for vehicles subjected to demanding conditions or specialized applications.

In summary, there are aftermarket axle spindle options available with enhanced durability or features. These may include performance spindles, upgraded materials, improved designs and engineering, specialized spindles, and customization options. When considering aftermarket spindles, it’s important to choose reputable manufacturers and consider factors such as compatibility, performance requirements, and intended use.

Are there recalls or common issues associated with specific axle spindle models?

Recalls and common issues can occur with specific axle spindle models. Here is a detailed explanation:

Axle spindles are critical components of a vehicle’s suspension system, responsible for supporting the weight of the vehicle and allowing the wheels to rotate. While axle spindle issues are not as common as some other automotive problems, they can still arise in certain situations or with specific models. It’s important to note that recalls and common issues can vary depending on the vehicle make, model, and year. Therefore, it’s essential to consult the manufacturer’s documentation or contact authorized dealerships to obtain the most accurate and up-to-date information regarding recalls or known problems associated with specific axle spindle models.

Recalls are typically issued by vehicle manufacturers or regulatory agencies when a safety-related defect or non-compliance with safety standards is identified in a specific component or vehicle model. When it comes to axle spindles, recalls may be issued if there is evidence of a manufacturing defect, design flaw, or other issues that could compromise the performance, durability, or safety of the axle spindle. Recalls are intended to address these concerns and ensure that affected vehicles are repaired or modified to rectify the problem.

Common issues associated with specific axle spindle models can also arise due to various factors. These issues may be reported by vehicle owners, observed by mechanics or technicians, or identified through data analysis. Common issues can include premature wear, excessive play, bearing failures, or other forms of damage or deterioration that affect the functionality or reliability of the axle spindle.

To determine if there are any recalls or common issues associated with a specific axle spindle model, follow these steps:

- Refer to Manufacturer’s Documentation: Check the manufacturer’s documentation, such as owner’s manuals, maintenance guides, or technical service bulletins. These resources may provide information about known issues, recalls, or recommended maintenance procedures for the axle spindle.

- Contact Authorized Dealerships: Reach out to authorized dealerships or service centers for the vehicle make and model. They often have access to the latest information regarding recalls or common axle spindle issues. Provide them with the specific details of your vehicle, including the make, model, year, and vehicle identification number (VIN) if requested.

- Check Government Recall Databases: Government agencies responsible for vehicle safety, such as the National Highway Traffic Safety Administration (NHTSA) in the United States, maintain databases of recalls. Visit their websites and search for any recalls associated with the specific vehicle make, model, and year.

- Online Forums and Communities: Explore online automotive forums and communities dedicated to the specific vehicle make or model. These platforms often provide valuable insights from owners who may have encountered axle spindle issues or recalls. However, exercise caution and verify the information obtained from such sources, as it may not always be accurate or up to date.

By following these steps, you can gather information about recalls or common issues associated with specific axle spindle models. If a recall or known issue is identified, it’s important to take appropriate action by contacting authorized repair facilities or dealerships to address the problem promptly.

It’s worth noting that not all axle spindle models may have recalls or common issues. Vehicle manufacturers strive to design and produce reliable components, and any potential problems are typically addressed through quality control measures and continuous improvement processes. However, occasional issues can still arise, particularly in specific production runs or under certain operating conditions.

In summary, recalls and common issues can occur with specific axle spindle models. Recalls are typically issued by manufacturers or regulatory agencies to address safety-related defects or non-compliance with safety standards. Common issues can include premature wear, excessive play, bearing failures, or other forms of damage or deterioration. To obtain accurate information about recalls or known issues, refer to the manufacturer’s documentation, contact authorized dealerships, check government recall databases, and explore online forums and communities dedicated to the specific vehicle make or model.

How does a damaged or bent axle spindle impact the performance of a vehicle?

A damaged or bent axle spindle can significantly impact the performance and safety of a vehicle. Here’s a detailed explanation:

When the axle spindle is damaged or bent, it can cause various issues that affect the overall performance and handling of the vehicle. Here are some ways a damaged or bent axle spindle can impact a vehicle:

- Wheel Misalignment: A damaged or bent axle spindle can result in wheel misalignment. This misalignment can cause uneven tire wear, reduced traction, and compromised handling. The vehicle may pull to one side, and the steering may feel unstable or imprecise. Wheel misalignment can also lead to increased rolling resistance, negatively impacting fuel efficiency.

- Vibration and Shaking: A bent axle spindle can cause vibrations and shaking in the vehicle, particularly at higher speeds. The imbalance created by the bent spindle can result in uneven tire rotation and wheel wobbling, leading to an uncomfortable and potentially unsafe driving experience.

- Braking Issues: A damaged axle spindle can affect the performance of the braking system. Uneven wheel rotation caused by a bent spindle can result in inconsistent braking force distribution. This can lead to longer braking distances, reduced braking efficiency, and potentially compromised safety in emergency braking situations.

- Suspension Component Stress: A damaged or bent axle spindle can place excessive stress on other suspension components, such as wheel bearings, control arms, or steering linkage. The misalignment and increased forces can accelerate wear and tear on these components, leading to premature failure and costly repairs.

- Handling and Stability: A compromised axle spindle can negatively impact the vehicle’s handling and stability. It can cause unpredictable steering response, reduced cornering ability, and decreased overall stability during maneuvers. This can increase the risk of loss of control and accidents, especially in emergency or evasive driving situations.

It’s important to address a damaged or bent axle spindle promptly. Continuing to drive with a damaged spindle can exacerbate the issues mentioned above and potentially cause further damage to other components of the suspension system. If you suspect a problem with the axle spindle, it’s recommended to have the vehicle inspected by a qualified mechanic or technician who can accurately diagnose the issue and perform the necessary repairs or replacement.

In summary, a damaged or bent axle spindle can have a significant impact on the performance and safety of a vehicle. It can cause wheel misalignment, vibrations, braking issues, stress on suspension components, and compromised handling and stability. Prompt attention and repair are crucial to ensure the vehicle’s optimal performance and to maintain safety on the road.

editor by CX 2024-02-15

China wholesaler 4.3m long high strength Carbon fiber Drive Shaft carbon fiber transmission shaft Propeller Shaft near me factory

Software: printing products, K-power NE-thirty 3510 24V reduction ratio 136 harmonic DC motor gearbox papermaking gear

Condition: Carbon Fiber Tube

Solution Kind: Carbon Fiber

Working Temperature: -eighty~+ a hundred and fifty degree

H Content (%): .001%

Ash Content material (%): 001%

Risky: Non

Material: a hundred% Carbon Fiber

Coloration: Black Color

Area: Glossy/ Matte/ fifty% Shiny

Surface area Treatment: 3K or UD

Duration: max 8. meter

OEM: Satisfactory

Usage: transmission shaft

Gain: gentle excess weight

Packaging Specifics: Plastic bag with paper&wooden box

Port: HangZhou

four.3m long high toughness Carbon fiber Drive Shaft carbon fiber transmission shaft Propeller Shaft

- Surface:3K simple 3K twill(can be customized)

- Complete: Glossy(can be tailored matte or sleek or coloration portray)

- Material: carbon fiber+ epoxy resin

- OD:300mm (can be customized 5~400mm)

- Thickness:3mm (can be tailored .5~50mm)

- Length:4.3m(can be tailored 5~6000mm)

- Packing: Plastic bag with paper & Delivery sturdy electrical power instrument ev conversion package electric powered motors computerized gearbox for tractor dump truck wood box

We welcome customzied. ?

How to Substitute the Travel Shaft

A number of distinct capabilities in a car are crucial to its working, but the driveshaft is probably the component that requirements to be understood the most. A broken or damaged driveshaft can harm several other auto parts. This report will describe how this element performs and some of the indications that it may possibly need restore. This report is for the typical individual who desires to fix their automobile on their personal but may not be acquainted with mechanical repairs or even driveshaft mechanics. You can simply click the website link under for a lot more information.

Repair destroyed driveshafts

If you possess a vehicle, you should know that the driveshaft is an integral component of the vehicle’s driveline. They make certain productive transmission of electricity from the engine to the wheels and generate. Nonetheless, if your driveshaft is destroyed or cracked, your car will not perform properly. To maintain your car protected and running at peak performance, you should have it fixed as before long as achievable. Here are some easy steps to substitute the generate shaft.

1st, diagnose the trigger of the generate shaft damage. If your car is generating strange noises, the driveshaft might be broken. This is since worn bushings and bearings assist the generate shaft. Consequently, the rotation of the drive shaft is afflicted. The sounds will be squeaks, dings or rattles. After the problem has been identified, it is time to restore the ruined drive shaft.

Pros can repair your driveshaft at reasonably minimal expense. Fees range depending on the type of travel shaft and its condition. Axle repairs can range from $three hundred to $1,000. Labor is generally only around $two hundred. A straightforward mend can cost in between $one hundred fifty and $1700. You will save hundreds of pounds if you happen to be in a position to resolve the difficulty by yourself. You could require to commit a handful of far more hours educating by yourself about the dilemma before handing it over to a expert for proper analysis and repair.

The value of fixing a ruined driveshaft varies by design and maker. It can price as a lot as $2,000 relying on components and labor. Whilst labor charges can range, elements and labor are normally close to $70. On common, a broken driveshaft mend costs in between $four hundred and $600. Even so, these components can be a lot more high-priced than that. If you never want to commit cash on unnecessarily high-priced repairs, you may want to spend a minor more.

Find out how generate shafts perform

Whilst a auto engine might be one particular of the most sophisticated parts in your car, the driveshaft has an equally important occupation. The driveshaft transmits the energy of the motor to the wheels, turning the wheels and producing the car shift. Driveshaft torque refers to the power associated with rotational motion. Travel shafts must be capable to face up to extreme problems or they might split. Driveshafts are not developed to bend, so understanding how they work is vital to the correct performing of the vehicle.

The push shaft contains a lot of parts. The CV connector is a single of them. This is the final cease prior to the wheels spin. CV joints are also known as “doughnut” joints. The CV joint will help balance the load on the driveshaft, the final quit in between the engine and the last generate assembly. Ultimately, the axle is a single rotating shaft that transmits electrical power from the closing push assembly to the wheels.

Different varieties of push shafts have distinct quantities of joints. They transmit torque from the motor to the wheels and need to accommodate variations in duration and angle. The drive shaft of a entrance-wheel travel motor vehicle normally consists of a connecting shaft, an interior consistent velocity joint and an outer mounted joint. They also have anti-lock method rings and torsional dampers to support them operate efficiently. This guide will assist you recognize the principles of driveshafts and maintain your vehicle in excellent form.

The CV joint is the heart of the driveshaft, it permits the wheels of the car to shift at a continual pace. The connector also helps transmit electrical power successfully. You can discover much more about CV joint driveshafts by looking at the top 3 driveshaft queries

The U-joint on the intermediate shaft could be worn or destroyed. Small deviations in these joints can trigger slight vibrations and wobble. Over time, these vibrations can use out drivetrain factors, like U-joints and differential seals. Added wear on the middle support bearing is also envisioned. If your driveshaft is leaking oil, the following phase is to check out your transmission.

The push shaft is an important part of the vehicle. They transmit electricity from the engine to the transmission. They also connect the axles and CV joints. When these components are in great problem, they transmit electrical power to the wheels. If you find them free or stuck, it can lead to the vehicle to bounce. To make certain suitable torque transfer, your auto needs to continue to be on the road. Whilst rough roads are typical, bumps and bumps are widespread.

Typical symptoms of ruined driveshafts

If your automobile vibrates heavily beneath, you may possibly be dealing with a faulty propshaft. This problem restrictions your total handle of the motor vehicle and cannot be ignored. If you listen to this noise regularly, the dilemma may be the result in and must be identified as shortly as feasible. Listed here are some common symptoms of a damaged driveshaft. If you experience this sounds although driving, you ought to have your vehicle inspected by a mechanic.

A clanging seem can also be one of the signs of a damaged driveshaft. A ding might be a indication of a faulty U-joint or centre bearing. This can also be a symptom of worn centre bearings. To keep your vehicle protected and functioning appropriately, it is best to have your driveshaft inspected by a qualified mechanic. This can avoid serious injury to your car.

A worn push shaft can lead to difficulty turning, which can be a significant protection issue. Fortunately, there are a lot of approaches to explain to if your driveshaft needs provider. The very first point you can do is verify the u-joint by itself. If it moves as well significantly or as well small in any path, it almost certainly means your driveshaft is defective. Also, rust on the bearing cap seals could show a defective generate shaft.

The up coming time your vehicle rattles, it might be time for a mechanic to check out it out. No matter whether your motor vehicle has a manual or computerized transmission, the driveshaft plays an critical part in your vehicle’s efficiency. When one particular or each driveshafts fall short, it can make the vehicle unsafe or not possible to travel. As a result, you should have your car inspected by a mechanic as shortly as attainable to avoid further issues.

Your motor vehicle should also be often lubricated with grease and chain to stop corrosion. This will avert grease from escaping and leading to grime and grease to build up. Another typical indicator is a soiled driveshaft. Make confident your mobile phone is cost-free of debris and in good condition. Finally, make certain the driveshaft chain and go over are in spot. In most instances, if you discover any of these frequent indicators, your vehicle’s driveshaft ought to be replaced.

Other indications of a broken driveshaft contain uneven wheel rotation, difficulty turning the vehicle, and increased drag when trying to change. A worn U-joint also inhibits the capability of the steering wheel to flip, producing it a lot more tough to flip. Another signal of a faulty driveshaft is the shuddering sound the car makes when accelerating. Automobiles with ruined driveshafts should be inspected as soon as possible to keep away from pricey repairs.